CJR Propulsion offers the fastest replacement service for fully optimised Class S propellers

How long does boat propeller replacement take?

CJR Propulsion is one of the world’s most respected marine propeller manufacturers. Our emergency boat propeller replacement service can provide our clients with an identical copy of their propellers in as little as two weeks*.

Broken propellers are a frustrating and costly problem, especially for owners relying on a functioning vessel for revenue. Perhaps you’re a superyacht owner missing out on hundreds of thousands of pounds in valuable charter time with propellers that aren’t functioning? No matter the deadline you’re facing, get in touch with the CJR team to discuss your requirements. We can get your boat back to its best with a fast turnaround.

Catering to commercial and private clients globally

The service has specifically been developed to meet the needs of yacht charter businesses, boat owners, and new build and refit boat yards, who need a high quality but timely solution for damaged or broken propellers, or those experiencing propeller performance issues.

Though based in Southampton in the UK, by leveraging our global network of partners, we can visit your vessel anywhere in the world. Clients’ vessels moored among the palm tree-lined waters of Florida, to the breezy blue skies of the South of France, can rely on the CJR team to travel to them wherever they are, and deliver an exact copy of their propellers in as little as two weeks.

An identical copy of your propellers

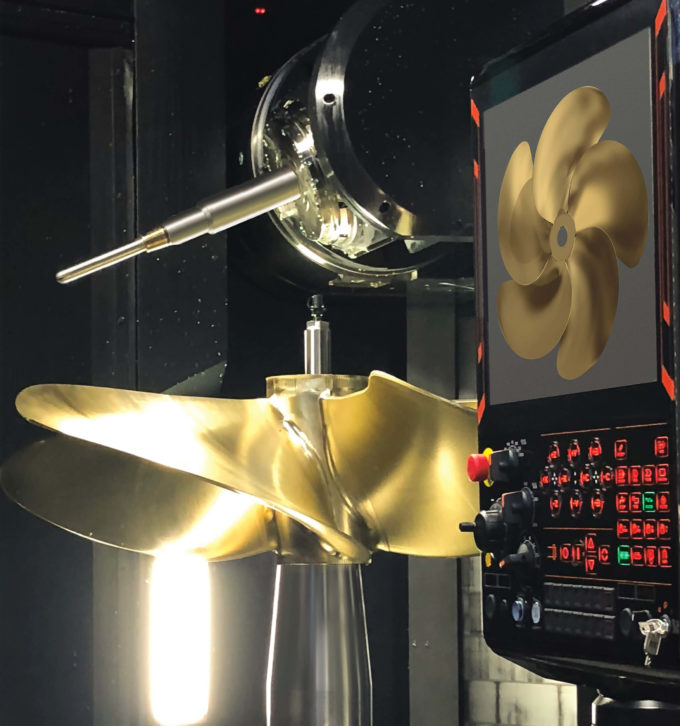

Forget needing to join a ‘replacement club’ and making do with standard patterns and lower quality Class 1 products. If you damage your superyacht, motor yacht or commercial vessel propellers, and a repair isn’t possible, CJR’s rapid replacement service can supply fully-optimised, Class S propellers in just 14 days. We do this by creating a highly-accurate 3D scan of the existing propellers and hull form, before producing an identical replacement.

A custom, fully optimised solution

Alternatively, to gain potentially significant performance and ride comfort improvements, we can design and manufacture an entirely new set of fully-optimised replacement propellers, using advanced computational fluid dynamics (CFD).

Our bespoke software visualises your boat’s specific hull form and entire stern gear set-up before performing hundreds of iterative simulations to determine the optimal design and position for each vessel. This creates a unique design that can increase performance, reduce vibration and cavitation, and extend the life of your propellers. It is a long-term solution which reduces the likelihood of a repair or replacement being needed in the future. We have increased the top speed of several vessels by up to two knots, just by switching to our propellers. This service can also be completed in as little as two weeks.

Our manufacturing process

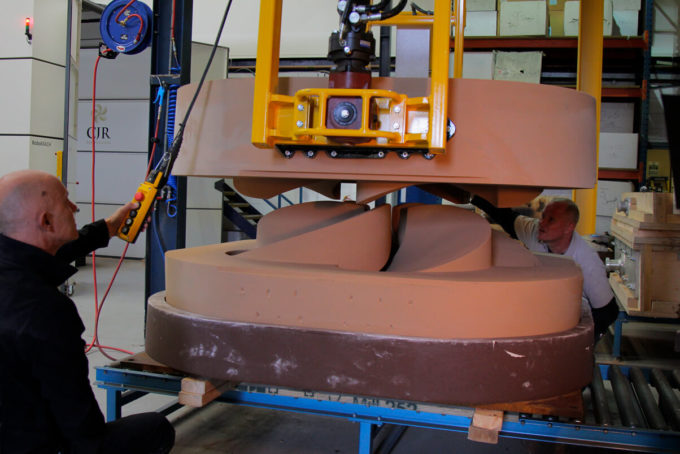

This uncompromising replacement service has been achieved through a four-million-pound investment in our design and manufacturing facilities. This includes combining CFD with advanced ‘patternless’ robotic mould making, multiple 5-axis CNC machining centres, and the production automation technology required to tie every step of the process together.

Because we don’t rely on hand finishing, standard patterns or a best-fit mentality, every propeller using this emergency service can be certified ISO 484/ 2-1981 Class S, which requires the highest levels of production accuracy and the adherence to the smallest tolerances.

How much does it cost to replace a boat propeller?

Whether you opt for an identical copy of your existing propellers or a fully optimised custom set, the overall cost of each project is bespoke to our client’s specific needs, timeframe and location. Contact the CJR team today to discuss your budget and requirements.

Take it from our satisfied clients…

“Due to unexpected circumstances with our usual propeller supplier we had to urgently find a new supplier for a propeller for a fully classed vessel.

The vessel was completed, sitting on the dock, waiting to be launched so we could commission her and deliver to the client. So we had very little time.

We contacted CJR and from there on we got quickly back on track. Using their rapid service, CJR was able to design, fabricate and certify the propeller in a matter of only some weeks.

Thanks to CJR, we were able to keep the schedule and deliver the vessel to the owner on time.”

Juha Granqvist, Sales Manager

Uudenkaupungin Työvene Oy

*We are capable of a swift turnaround depending on your specific timeline and budget. Get in touch with us today to discuss your unique requirements.

Get in Touch

CJR combines decades of experience with continuous investment in the latest technology and engineering prowess. Just drop us a note to find out more about how we can help you.

CONTACT US