The way a propeller is designed and manufactured can significantly improve speed and increase ride comfort. It can also reduce long-term costs thanks to lower fuel consumption and an extended working life. The case study below compares CFD-designed CNC-machined Class S propellers against hand-finished Class 1 propellers, so you can make a data-driven decision when specifying your next propeller and sterngear package.

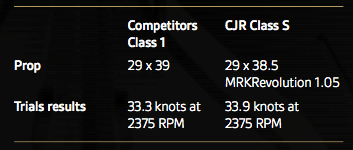

Trials comparison between CJR Class S CNC-machined propellers and hand-finished Class 1 propellers

- Vessel: 2019 57′ production motoryacht

- Date: 25 June 2019

- Location: Poole, UK

Speed: Trials demonstrate a 0.6 knot speed increase with the CNC-machined Class S propeller.

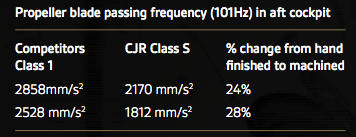

Vibration analysis at maximum RPM: The CNC-machined propeller delivers roughly a 25% reduction in vibration levels at the blade passing frequency.

In addition, vibration levels are less than half at the shaft frequency when trialling the CNC-machined prop.

Key features of CJR’s CFD-designed CNC-machined propellers

Designed using advanced computational fluid dynamics for each individual vessel, whilst considering expected use, location and owner’s performance preferences

- Manufactured using pattern-less mould-making and five-axis CNC machining for total adherence to the CAD design

- Significantly improved propulsive efficiency due to bespoke nature and optimised rake and skew – reducing engine load by up to 3% at the same RPM to reduce fuel burn by up to 10%, or increase top speed by up to two knots

- Vibration reduced by up to 50% compared to standard pattern props for improved ride comfort

- Minimised cavitation for extended working life and extended replacement cycle

- Manufactured to any classification society rules, including all IACS societies

Not all propulsion systems are created equal

We don’t use standard off-the-shelf patterns, or a ‘hand-made’ close match approach, and we always design and manufacture for a specific vessel. This provides our customers with peace of mind that everything we supply is going to perform exactly as expected, with maximum performance, efficiency, longevity and ride comfort.

Reduced fuel consumption

Our customers report that our CNC-machined Class S propellers have also delivered significant cost-savings in terms of reduced fuel consumption.

“Working with CJR has been a revelation. As they have demonstrated, technology can dramatically improve the achievable standard for performance and vibration levels. We have learnt that fully-machined Class S propellers are the only option for minimising vibration, putting less strain on the sterngear system and extending the lifespan of the vessel, plus improving crew comfort. The vessel is now saving a significant volume of fuel each day – equating to approximately 8–10% of annual usage. For us, this is an incredible saving and demonstrates the value CJR provides its customers.” – Bob Mainprize, Owner of Mainprize Offshore

Designing props for optimum performance

Our end-to-end design, engineering and manufacturing solution has been specifically developed to provide fully-optimised propulsion packages that are proven to go faster, reduce fuel consumption, last longer and increase ride comfort.*

Whether you have a brand-new motor yacht in build, require a replacement solution due to damage, or are experiencing issues with your current set-up, we can help. Our CFD designed, CNC machined, Class S propellers and sterngear packages can be manufactured in as little as two weeks, using our rapid production process. We are recognised as a key supplier to leading boat builders around the world, including Sunseeker, Princess, Galeon and Ferretti.

With decades of experience, combined with the very latest technology, including advanced robotics and machine learning, and we know what it takes to design and manufacture the perfect propeller and sterngear package. We also understand how the design of your propellers and sterngear need to match your individual requirements. Because of this, we work with you to understand how your vessel is going to be used and design a solution to match, and always at a competitive price.

Find out more

Follow CJR on LinkedIn or take a look at our products and services page.

*Compared to hand finished propellers