CJR Fabrication has now commissioned the latest addition to its manufacturing offering with the ‘Hydra – Ovaliser’, a bespoke tube manipulation and bending tool.

The Hydra – Ovaliser has been developed in-house and will be used to create mirror- finish oval tubes up to 5.8 metres in a single length, replacing the commonly used but less precise ‘chain-driven system’. The new equipment is designed to extrude oval or round tubes for all manner of architectural and design-focused applications but primarily will be used for bespoke handrails.

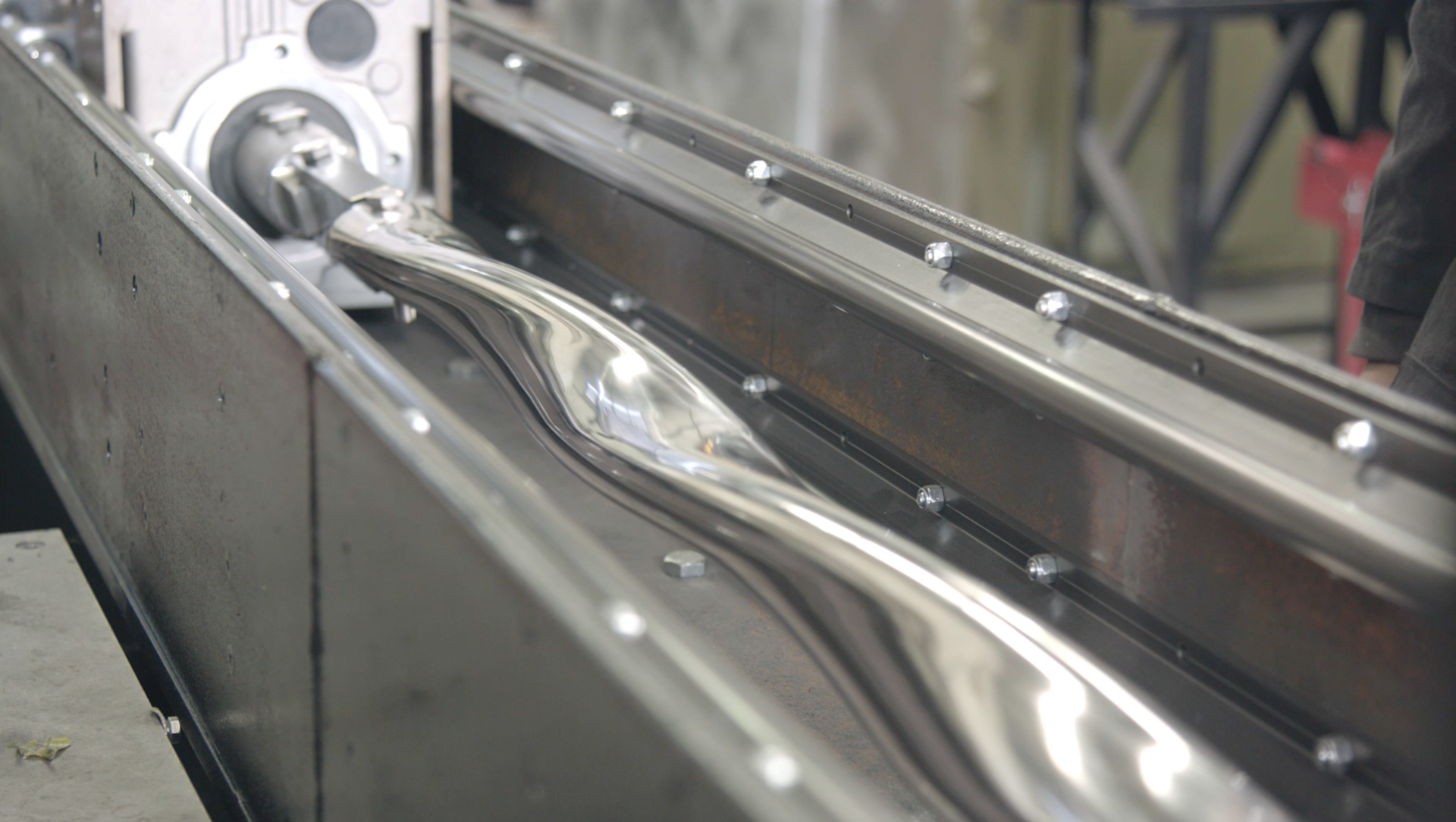

The Hydra – Ovaliser promises to produce exceptional results through the use of a powerful, six-meter-long hydraulic ram, which pulls the tube at a constant speed and resistance to deliver a perfect, ripple-free finish, every time. The new apparatus also benefits from a precision carriage system, based on Igus Track systems, which ensures a perfectly aligned delivery into the equipment. Multiple sections of tube can also be easily joined with CJR Fabrications’ ‘high- shine’ cast joiners.

“We are lucky enough to work with some of the world’s most prestigious yacht brands, as well as several leading architects and luxury building groups, all of which rightly expect the very highest levels of quality but still demand a competitive price and rapid turnaround. The new Hydra – Ovaliser fits all of these requirements and positions CJR Fabrication above the competition and uniquely equipped to deliver an even broader range of products of the highest quality,” commented Michelle Davies, General Manager for CJR Fabrication.

CJR Fabrication is already a leading player in this market, producing over 3.5 kilometres of oval tubes last year alone. The new equipment is suitable for 316L stainless steel and aluminium tubes from 23–168mm in diameter, and can draw around six metres of tube every minute.