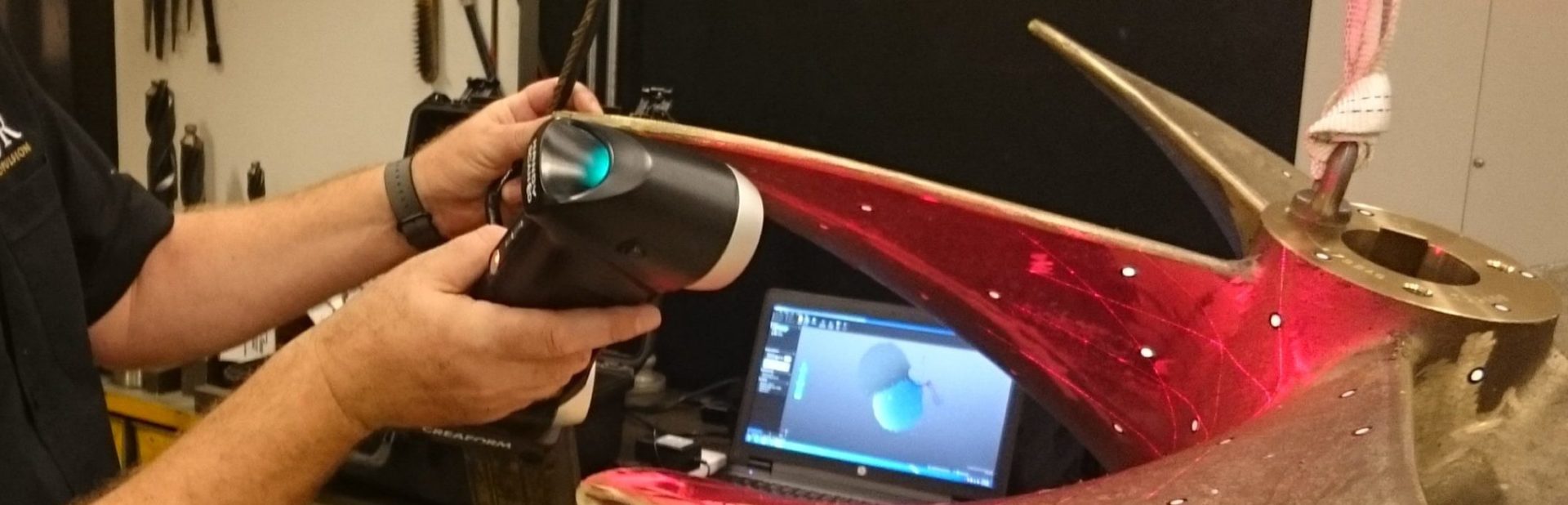

CJR Propulsion is always on the look out for new technology to improve the performance of its products or to make the design and manufacturing process easier and more efficient for its customers. The arrival of CJR’s latest investment, an advanced portable 3D scanner, is already making an impact on both these fronts.

3D scanners are still relatively new and it is only recently that falling costs and increasing accuracy have converged to make the latest generation of products highly attractive to the propulsion industry. 3D scanners, and more specifically portable scanners, now promise to reduce prototyping costs, increase product repeatability, and enable analysis of even the most complex propeller and hull forms in situ.

For CJR, which works on a high percentage of bespoke re t and repair projects, the portability of the new scanner was of particular interest, as Simon Lewis, Head of CFD and Propeller Design comments:

“Our reputation for maximising efficiency means we get a lot of enquiries related to existing vessels that might need just one prop replaced or where they are looking to increase efficiency through a new stern gear or propulsion system. Whereas historically, replacing an existing propeller meant removing it from the vessel and sending it to our facility to be scanned, the new portable scanner means propellers can be scanned on the dockside – often without removing them from the vessel. Likewise, gaining a true understanding of a hull form is the only way to ensure you are maximising propulsion efficiency. For an older vessel, with no technical drawings available, being able to scan the entire hull, including appendages, in just minutes has noticeable benefits for us and the customer.”

Using the new scanner, replacement propellers can be rapidly designed by importing the 3D scan directly into CJR’s bespoke design programme before a 3D printer is used to create a full-size mould. The propeller can then be cast from the reverse mould before being tested against the original scan to ensure the replacement propeller perfectly matches the old one.

The new 3D scanner, from one of the world’s leading manufacturers, is able to capture 480,000 measurements every second from its eight lasers and is 25 times faster and 40% more accurate than previous models, with an error tolerance of just 0.030 mm. With this level of accuracy, the new scanner will also play an important role in ensuring every product that leaves CJR’s factory meets both the original design and CJR’s own quality standards, as Simon concludes:

“We have invested in every stage of the design and manufacturing process. From our CFD (Computational Fluid Dynamics) and advanced modelling software, to robotic finishing tools, human experience has consistently made way for automated, technical precision. The new scanner could be considered the final tick in that process – capable of checking every new prop design we produce against the original specification to ensure the whole process is working as it should.”

CJR is also now able to offer 3D scanning on a consultancy basis so if you require detailed and highly accurate insight into an existing hull or any other area, get in touch.

“Being able to scan the entire hull, including appendages, in just minutes has noticeable benefits for us and the customer.”