For both bespoke and new production vessels, engineering complexities are around every corner. Boat designers and builders must find reliable partners to help overcome specific challenges with unique solutions. Here, Mark Patterson, lead design engineer for CJR Fabrication, discusses how he helps support leading brands to go from design concept to production.

It’s a call we get relatively often. A customer has a challenge that they’re not sure how to overcome and they ask us to work with them to find an effective solution. It is increasingly becoming a key part of our business; especially as other fabrication specialists have reduced or removed their engineering departments or fallen behind in investments in the latest CAD-based technology. Thankfully, we’ve gone the other way and grown our in-house capabilities to support even the most complex requirements.

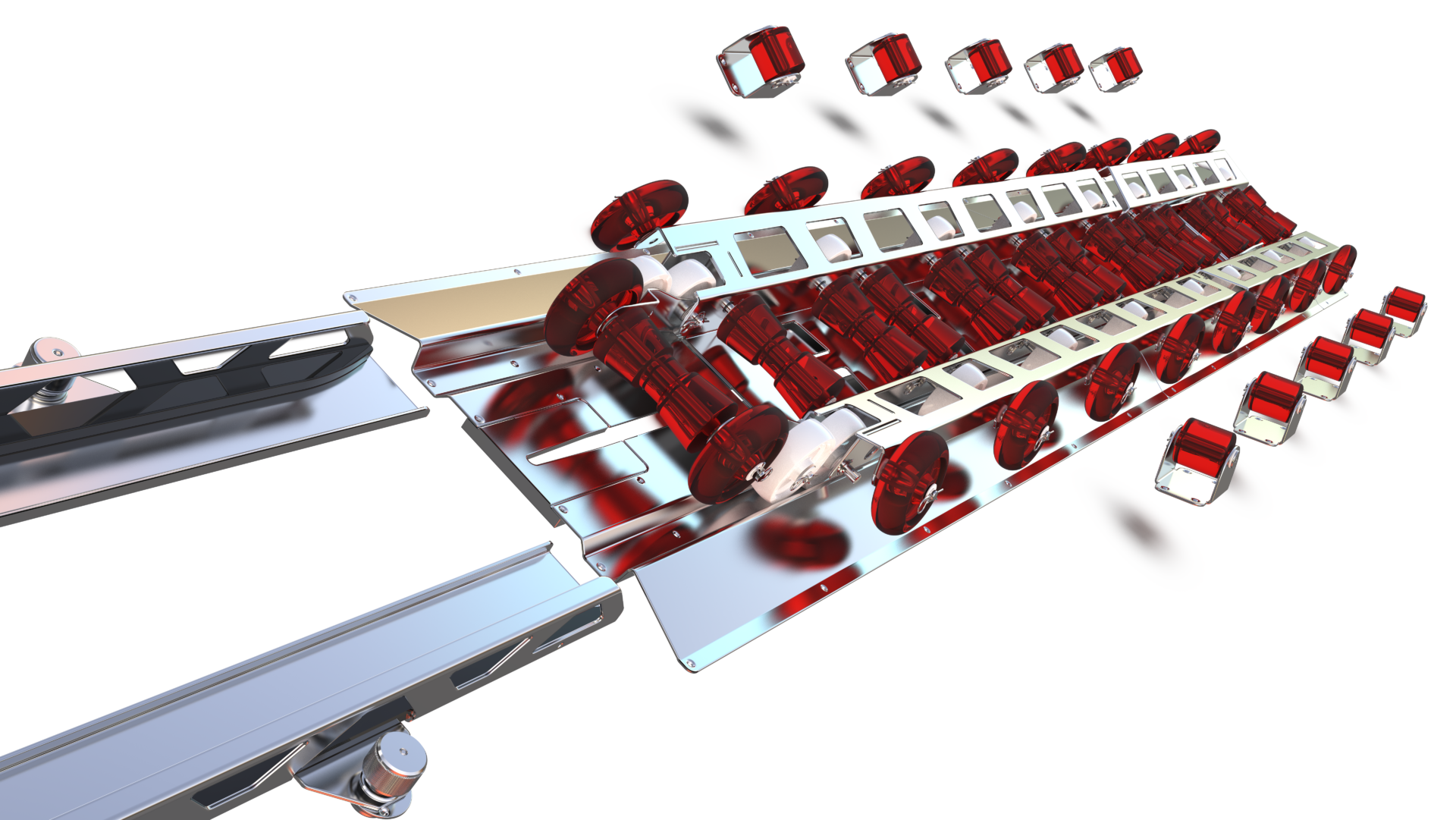

One recent example is a tender launch and recovery system. The builder needed to find a way to launch a standard Williams tender, but due to other design requirements, the garage opening had only 150mm clearance for the entire system – not nearly enough space for an off-the-shelf product. The builder didn’t want to compromise in other areas so came to us to find an effective remedy.

As is always the case, the restricted space was just one of the issues we had to overcome, our solution had to be incredibly lightweight, obviously strong but also cost-effective. Three things which don’t often fit comfortably together! However, using the CAD designs we were supplied, and working closely with the builder’s design team, we identified a new concept that met all the requirements. One of the ways we did this was by using a lot of press fit bearings and complex sheet folding, which massively reduced the number of welds required and made installation quick and easy, with the system assembled using a number of smaller parts. This was only possible by having the technical data we needed from the customer and by utilising our advanced design software and manufacturing tools to test our ideas before we get to the physical prototyping stage.

Another good demonstration of our approach was for a retractable anchor system. In this instance, the level of collaboration required was even greater. We literally worked in true partnership with the builder to develop a solution that worked both technically and aesthetically. We went back and forth to discuss issues, how we could remove them and how to make the chosen design as simple as possible, reducing the number of required man hours, parts and raw materials.

The finished product is fantastic, a true bespoke system to launch and retract the anchor. It has a beautiful electro- polished finish, with a hidden bow door mechanism and is designed around the mouldings to ensure seamless operation. I wish we could say who it’s for but you’ll see it soon I hope!

With other projects, our role can be slightly different. We recently started working with a leading exhaust manufacturer where they wanted us to use their CAD drawings to fabricate a fully-jacketed exhaust system. In this instance, the finalised design was already available so we were manufacturing to their specification but it still required all our engineering capabilities to tie together the GRP components with our fabricated metal elements. We did a number of site visits to understand the challenge and agree the solution through prototyping and testing, we also managed to complete the entire project in less than six weeks. Again, it is our internal expertise and investments in the latest manufacturing tools that made this possible and I don’t think many other fabricators could have done it, certainly not in that timeframe.